APRIL 2012

CREATE COMPRESSED AIR ENERGY SAVINGS OF UP TO 50%

With a price on carbon due to be set on 1st July 2012, reducing energy costs has become even more important for industry. Gilbert McLean, the National Key Account Manager of the AirAudit Division at CompAir Australasia discusses how energy savings of up to 50% can be made within a compressed air system.

With a price on carbon due to be set on 1st July 2012, reducing energy costs has become even more important for industry. Gilbert McLean, the National Key Account Manager of the AirAudit Division at CompAir Australasia discusses how energy savings of up to 50% can be made within a compressed air system.

‘Reducing the cost of energy has never been so important with the Clean Energy Bill 2011 placing new impetus on businesses to find ways to reduce their carbon emissions or face a hefty rise in their energy costs.

A price on carbon is due to be set on 1st July 2012 by the federal government. This will directly impact around 500 of the biggest polluters including a number of companies in the waste disposal sector, cement, chemicals and metal processing industries. However, the largest group of polluters to be affected by this Bill will be energy providers themselves – gas, electricity and coal retailers. Undoubtedly, they will pass some of this extra cost on to end users meaning directly or indirectly the carbon price will affect every business in New Zealand.

Partly as a result of the carbon price, The New Zealandn Energy Market Commission forecasts that nationally, nominal electricity prices will increase by 37% between 2011 and 2014.

‘A compressed air system is one of the largest consumers of energy in any business with energy costs accounting for approximately 80% of the lifetime costs of a compressor. However, compressed air also represents one of the greatest opportunities within a business to generate energy savings and reduce the associated carbon footprint.

‘The first step in reducing compressed air associated energy costs is to undergo a comprehensive audit.

At CompAir we deliver this service through AirAudit. This is a highly accurate, non-intrusive process which identifies areas of loss or inefficiencies within a compressed air system that meets the requirements of the New Zealandn Federal Government’s Energy Efficiency Opportunity Act, in conjunction with the National Greenhouse and Energy Reporting (NGERS) Act.

‘AirAudit follows a “Total Systems Integration Approach” and includes leak detection, demand- and supply- side flow analysis (end use), full measurement of power absorbed including power factor, actual flow rates and – where relevant – pressure and dew point.

‘AirAudit is performed to the highest standard, quoting accuracies of less than 5% and delivering detailed independent reports and analysis of a compressed air system. This includes recommendations for; leak correction, leak tracking (data management for repeat surveys), targeting of maintenance upgrades, flow demand characterisation and optimisation, a compressed air distribution summary, a comprehensive list of compressed air solutions, a risk assessment and a cost savings summary. Additionally a plan for ongoing energy cost reductions is provided.

‘The AirAudit can identify savings which can be created on both the demand and supply side of a compressed air system.

10-20% energy savings can be found on the supply side by improving;

Compressed air equipment; changes in shift patterns or production will change the demand for compressed air. It may be the case that upgrading the compressor to better meet these new demands will reduce the associated energy costs.

Compressor technology; where appropriate replacing a fixed speed compressor with a variable speed compressor will reduce energy costs. Variable speed technology matches output to exact requirements minimising off-load running.

Control & monitoring; implementing an energy management system will ensure a compressed air system can be controlled and monitored on an on-going basis for optimised energy usage.

Maintenance; following the recommended manufacturers maintenance schedule will ensure minimal wear and tear of consumable parts optimising system efficiency.

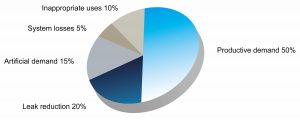

‘Additionally, up to 50% energy savings can be achieved by following the recommendations from the AirAudit’s detailed demand side analysis which will identify areas of improvement in; artificial demand, system dynamics, compressed air leak detection, system design as well as monitoring and sub-monitoring.

‘The cost of undergoing an AirAudit can be easily and quickly recovered through reduced system costs. Depending on your location and business type you may even be eligible for state or federal government funding to cover the cost of the AirAudit and the work to improve and optimise your compressed air system.

If you are applying for funding under the New Zealandn Federal Government’s Clean Technology Investment Program or the Clean Technology Food and Foundries Investment Program, an AirAudit will provide necessary support for your application to upgrade plant and equipment.

‘By identifying improvements in a compressed air system through an AirAudit and acting on these, it is possible to reduce power consumption and thereby reduce your associated energy costs. In turn you will also reduce compressed air system load as well as wear and tear which will extend the life of the compressed air system and deliver a greater return on your investment.’

Visit https://www.airaudit.com.au to calculate your potential energy savings.